What is a touchscreen on a computer? What is a touchscreen? Video about capacitive touch screen

More recently, the mobile device market could offer mainly push-button devices. Only occasionally did people find themselves in the hands of PDAs and other wonders that had touch screen. But times change, and technology does not stand still. Now the counters have almost completely gotten rid of push-button devices, providing a huge selection touch phones and tablets. At the same time, the variety of shapes, models and quality of gadgets is simply amazing. But they all have the same principle of input and output of information - a touch screen, which also has its own varieties. Let's look at what a touchscreen is, what types there are, and how to calibrate them.

Types of sensors

From the very beginning, let's define a touchscreen. A touchscreen is a device for entering any information into a phone or tablet. It is intended for the device to adequately perceive orders. Often a touchscreen (or sensor) is confused with a screen, but these are completely two different things.

The market today offers 4 main types of sensors for mobile devices:

- resistive;

- induction;

- capacitive;

- infrared.

They can be found at the most various devices and, in turn, their cost partially depends on the type of touchscreen. Let's take a closer look at each of them.

Resistive touchscreen

The resistive type of touchscreens works on the principle of responding to changes in geometric parameters. So, to get a response from the screen, you need to press it lightly. For this reason, we can immediately say about the disadvantages that a resistive touchscreen has. That this is a bad indicator is an understatement. It's all about the pressure itself, which causes the screen to deteriorate greatly. And although it’s quite easy to work with such a touchscreen with gloves or a stylus, the image turns out faded and scratches appear after a while.

Induction touchscreen

This type of touchscreen is located behind hard glass and can only be controlled using a special stylus. This is very inconvenient, since if this control item is lost or broken, you will need to shell out a considerable amount of money to purchase it.

Capacitive touchscreen

This type of touchscreen can be called an improved form of resistive sensors. It's also on top of the screen itself and spoils the image a bit. You can use either a stylus or your fingers to control it. It is possible to support multi-touch (which the previous options do not have) and the operating principle is based on the difference in electrical resistance. This allows you to enter information only when lung help touch. The disadvantage is that it is impossible to control third-party objects and gloved fingers.

Infrared touchscreen

These sensors work on the principle of an infrared grid. Infrared touchscreens are universal. They do not spoil the image, but, in turn, have a long response time and low accuracy.

Approximately 80% of touch devices use a capacitive sensor. It is as convenient as possible, inexpensive and at the same time has high response rates. Resistive is less common, but it is also used in mobile devices due to its low cost.

Touchscreen calibration

In some cases, when replacing a sensor or when malfunctioning, calibration is required. This procedure is not very complicated, but requires maximum attention, since the correct response of the touchscreen depends on it.

Touchscreen calibration is a sensor adjustment procedure that is carried out to improve the accuracy of the response to touching the device. To check whether this procedure is required or not, you need to remove protective film(if it’s not there, wipe the screen well), turn on any text editor and click on a specific letter. If a different sign appears on the screen instead of the selected option, calibration is required.

Calibration of resistive sensors

As a rule, resistive touch screens require the touchscreen to be calibrated immediately when turned on for the first time. Almost everyone forgets that this is a necessary monthly procedure after turning it on for the first time. Also, calibration must be carried out when replacing the screen, software failure, after a fall or impact.

It’s quite easy to calibrate a resistive sensor thanks to a built-in utility called ts_calibrate. To launch it, you need to go to the “Settings” section in the menu of your phone or tablet. Next, select “Phone Settings” and click on “Calibration”. As a result of these actions, the screen will turn black and a cross with a red dot located in the center will appear on it.

To calibrate a resistive touchscreen for a phone or tablet, you need to press the spot indicated by the dot. After each response, it moves and after the fourth press, all data about the grid is saved in the device’s memory. You can check after calibration using text input. If everything was done correctly, the specified letter or number will appear on the screen.

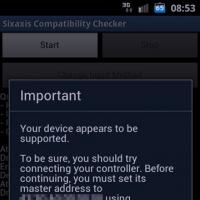

Capacitive Sensor Calibration

Quite rarely, but there are cases when capacitive sensors also have a grid that gets lost and needs to be calibrated. The problem lies in the procedure itself, since these touchscreens have a very complex design and the devices do not have built-in software.

Calibration must begin by downloading the TouchScreen Tune utility. It easily identifies and configures the touchscreen itself. What will this give? It’s just that in cases of a software failure or sensor replacement, it is impossible to independently set a grid that would work adequately. Thanks to this program, you can adjust everything to the desired values.

Additionally, it is worth noting malfunctions in the operation of the G-sensor, which determines the position of the smartphone or tablet in space. In some cases, it behaves inappropriately and makes using the gadget very difficult.

To calibrate the accelerometer of a device running Android OS you need:

- Go to engineering menu and simultaneously press the power button and volume down button.

- After the menu appears on the screen, using the same volume button, you need to scroll through the positions and find the Test Report item.

- In the list that opens, select G-Sensor cali.

After that, simply place the gadget on a flat surface and click on Do Calibration. You need to wait until the digital values stop appearing on the screen. Then press the volume up button twice and select Reboot. The accelerometer has been calibrated.

Precautions

It is necessary to calibrate the resistive touchscreen for tablets and phones once a month, since with active use of the device the entire grid is quickly damaged. If you do not do this, you may end up with an inadequate response to pressure and inconvenience in use. But, as a rule, there are no problems with calibration in this case.

Things are much more complicated with capacitive sensors. They do not initially require calibration as a standard procedure. For this reason, before you begin, you need to understand if the calibration will be carried out with major violations, then it will not be possible to return all the original settings that the touchscreen had. What does it mean? This is a complete loss of device functionality, which is almost impossible to restore even in service centers. Therefore, calibrating a capacitive sensor is only necessary if you are confident in your abilities and skills.

Now on the Internet on various technical forums on tablets and cell phones You can often see the word “touchscreen”. What is it? The word itself comes from the English phrase “touch screen”, consisting of two words: “touch” - touch, touch, touch and “screen” - screen. That is touchscreen is the touch screen of your phone, tablet, player or GPS navigator. That is, when you move your finger across the screen of your mobile gadget, you touch the touchscreen, which transmits data about the position of your finger operating system, which matches them with the image on the display.

In fact, it is a transparent touch glass that is placed on top of the screen matrix. For ease of replacement and repair, they are separate on most models of mobile devices.

When hit or dropped from a height, it is the touch glass that most often cracks and breaks. After this, it usually doesn't work. But the matrix itself is intact. And the touchscreen can be replaced separately from the display. Thus, it also plays a protective function.

How does the touchscreen work?

Today there are 3 main technologies that differ from each other.

1. Resistive touchscreen

The cheapest to produce and most resistant to dirt are touch screens. They consist of glass and a membrane, between which there are insulators. We press on the screen with a finger, pencil or stylus, the glass pushes through the insulator and closes with the membrane. And the controller reads the click and processes the received information. The main disadvantage of such touch screens is that they are dark (due to low light transmission) and short-lived. In addition, they really don’t like falling.

2. Capacitive screen

Here, special glass is already used, processed with a special material, through which current (alternating voltage) is supplied. You touch the touchscreen with your finger and a current leak occurs, which is detected by the sensors and transmitted to the controller. The reaction will only occur when pressed by hand. The screen will no longer respond to the glove.

This kind of touch glass is more durable than resistive glass, although they really don’t like dirt and water.

Due to the fact that there is no membrane, a capacitive touch screen has a light transmittance of about 90%.

3. Surface acoustic wave sensor

This is the most technically complex touch screen. It works by reading reflected surface acoustic waves and converting them into an electrical signal that is transmitted to the controller. Due to such complex technology, the touchscreen is very sensitive to dirt, vibration and electromagnetic interference.

The main advantage is the longest lifespan: about 50 million touches.

Every person constantly encounters a touchscreen when making calls on a smartphone or withdrawing money from an ATM. Let's take a closer look at the operating features of this device.

What is touchscreen, where is the technology used?

A touchscreen is a touch screen with which the user can give commands to the device by touching it. This technology has made it possible to abandon push-button phones; now to control a mobile device you need to interact with the screen - this is convenient and practical.

The name “touchscreen” comes from two English words – touch (touch) and screen (screen). Touch screen devices are ubiquitous, and these are not only mobile phones, but also:

- tablets;

- ATMs;

- information terminals at airports and train stations;

- household appliances, etc.

Although the touchscreen has become widespread in smartphones. Regardless of the device in which the technology is used, the operating principle is always the same - you issue commands by touching the desired elements on the screen. Then the algorithm of a specific program comes into play.

The basis of any touchscreen is a liquid crystal matrix. On the back side there are diodes (they serve as backlight), on the front side there are several layers that record pressing (in resistive screens) or touching (in capacitive taps).

Resistive touchscreen is an outdated technology

There are several systems used to create touch screens. The most common are resistive and capacitive technologies, which have significant differences. You can find out more about what a touchscreen is; the website describes different systems, indicating their pros and cons.

Old smartphones had resistive screens that required the use of styluses (small pointers with which the user gave commands to the phone). The resistive system is glass coated with an elastic film and a layer that conducts electricity.

There is empty space between these two elements. The display surface is protected by a special coating that protects the screen from scratches and other mechanical damage. But for better protection a film is provided (it came with old smartphones).

Resistive touchscreens have a number of disadvantages:

- the need to press on the screen (touching is more convenient);

- screen calibration resulting from redistribution of the mass of the insulating layer;

- rapid deterioration in the quality of the touchscreen (appearance of cracks, scratches, stains, etc.);

- short service life, which is explained precisely by the rapid appearance of damage;

- lack of sliding ability (as on modern smartphones), etc.

Today, resistive touchscreens are becoming increasingly rare. Smartphone manufacturers have abandoned them; now they are mainly used in ATMs and various terminals.

Capacitive touchscreen is the most popular system

This technology involves the use of glass with a conductive layer. Touching the display releases electric charge(at the location that was affected). Microcircuits record every touch on the display, transmitting this information to the touchscreen program.

Advantages of capacitive touchscreens:

- long service life and resistance to dirt;

- high level of transparency (at least 90%);

- better response to impact, reliability;

- excellent brightness (the picture looks clearer);

- moisture resistance, MultiTouch support.

Most often, smartphones use touch screens with protective tempered glass Gorilla Glass; it withstands light mechanical impacts, including scratches. Capacitive touchscreens began to replace their resistive counterparts in 2009.

But technology is improving, there is no doubt that in the future smartphones will be equipped with even more responsive, practical and durable displays.

Just recently, few could believe that phones with familiar buttons would give way to devices that were controlled by touching the screen. But times change and the demand for push-button phones is gradually falling, but on smartphones it is growing.

The term “touchscreen” was formed from two words - Touch and Screen, which is translated from English language translated as "touch screen". Yes, that's right - a touchscreen is a touchscreen that you touch when you use your smartphone or tablet. In fact, touch screens are found not only in the world of mobile technology. So, you could see them when you deposited funds into your account mobile device through a terminal, at an ATM, in ticket devices, etc.

Touch-screen owes its appearance to Western scientists. The very first samples were born in the second half of the 60s of the last century. Based on this, we can conclude that the touchscreen has been in use for more than 40 years. Before smartphones, they were used in ATMs, etc. Currently, every person who uses cellular communication, car navigators, visits banks and stores, encounters this technology, sometimes without even knowing what it is called. So, we figured out what a touchscreen is in phones. Essentially, this is the same as a finger touch display. It is perfectly used instead of a keyboard and is actively used in mobile technologies. The advantages of a touchscreen include protection from dust, moisture and other adverse environmental factors, as well as a high degree of reliability. If our touch device does not always respond to touch, or even refuses to do so, for example, it does not want to change the brightness on the iPad, most likely it is the touch-screen that has failed. It is relatively inexpensive (especially if we are interested in a resistive display), and it is easy to replace.

Touchscreen basis

The basis of any touchscreen is a liquid crystal matrix, which is actually a smaller copy of the one found in the monitor. On the back side there are backlight diodes, and on the front side there are a number of layers that record pressing (resistive screen) or touch (capacitive screen).

A person who is well versed in what a touchscreen is understands that most of the devices manufactured use a resistive touchscreen. This follows from their low cost and relative simplicity of design. Many Chinese “smartphones” that have flooded the market have a resistive type of screen, the manufacturing technology of which, by the way, appeared earlier than capacitive.

Types of touch screens

Touch screens are divided into resistive, matrix, projected capacitive, surface acoustic wave touch screens, infrared, optical, strain gauge, DST and induction touch screens.

Resistive touch screens

They are divided into four-wire and five-wire.

The resistive screen sensor consists of two transparent plastic plates with a thin conductive mesh that are located on the surface of a conventional liquid crystal screen. Between the plates there is a transparent dielectric layer. The program displays a graphical interactive interface, which, thanks to the transparent materials on the matrix, is clearly visible. When responding to a program request, the user clicks on the desired interface point (for example, an image of a button). - The plastic dielectric diverges, the plastic plates come into contact, supplying current from the electrode of one to the grid of the other. The appearance of current is recorded by the recording controller, which, in accordance with the coordinate grid, will determine the pressing point. The coordinates of the point are entered into the program and processed according to the established algorithms.

Four-wire screen

The resistive touch screen consists of a glass panel and a flexible plastic membrane. A resistive coating is applied to both the panel and the membrane. The space between the glass and the membrane is filled with micro-insulators, which are evenly distributed over the active area of the screen and reliably isolate conductive surfaces. When the screen is pressed, the panel and membrane are closed, and the controller, using an analog-to-digital converter, registers the change in resistance and converts it into touch coordinates (X and Y). In general terms, the reading algorithm is as follows:

A voltage of +5V is applied to the upper electrode, and the lower one is grounded. The left and right are short-circuited, and the voltage on them is checked. This voltage corresponds to the Y-coordinate of the screen.

Similarly, +5V and ground are supplied to the left and right electrodes, and the X-coordinate is read from the top and bottom.

There are also eight-wire touch screens. They improve tracking accuracy, but do not improve reliability.

Five-wire screen

The five-wire screen is more reliable due to the fact that the resistive coating on the membrane is replaced by a conductive one (the 5-wire screen continues to work even with a cut through membrane). The rear glass has a resistive coating with four electrodes at the corners.

Initially, all four electrodes are grounded, and the membrane is “pulled up” by a resistor to +5V. The voltage level on the membrane is constantly monitored by an analog-to-digital converter. When nothing is touching the touch screen, the voltage is 5V.

As soon as the screen is pressed, the microprocessor detects the change in membrane voltage and begins to calculate the coordinates of the touch as follows:

A voltage of +5V is applied to the two right electrodes, the left ones are grounded. The voltage on the screen corresponds to the X-coordinate.

The Y-coordinate is read by connecting both upper electrodes to +5V and to ground both lower ones.

Resistive touch screens are cheap and resistant to contamination. Resistive screens respond to touch with any smooth, hard object: a hand (bare or gloved), a stylus, credit card, mediator. They are used wherever vandalism and low temperatures are possible: for automation of industrial processes, in medicine, in the service sector (POS terminals), in personal electronics (PDA). The best samples provide an accuracy of 4096x4096 pixels.

The disadvantages of resistive screens are low light transmission (no more than 85% for 5-wire models and even lower for 4-wire models), low durability (no more than 35 million clicks per point) and insufficient resistance to vandalism (the film is easy to cut).

Matrix touch screens

The design is similar to resistive, but simplified to the limit. Horizontal conductors are applied to the glass, and vertical conductors are applied to the membrane.

When you touch the screen, the conductors touch. The controller determines which conductors are shorted and transmits the corresponding coordinates to the microprocessor.

They have very low accuracy. Interface elements have to be specially positioned taking into account the cells of the matrix screen. The only advantage is simplicity, cheapness and unpretentiousness. Typically matrix screens are queried row by row (similar to a button matrix); this allows you to set up multi-touch. They are gradually being replaced by resistive ones.

Capacitive touch screens

A capacitive (or surface capacitive) screen takes advantage of the fact that a large capacitance object conducts alternating current.

A capacitive touch screen is a glass panel coated with a transparent resistive material (usually an alloy of indium oxide and tin oxide). Electrodes located at the corners of the screen apply a small alternating voltage (the same for all corners) to the conductive layer. When you touch the screen with your finger or other conductive object, current leaks. Moreover, the closer the finger is to the electrode, the lower the screen resistance, which means the greater the current. The current in all four corners is recorded by sensors and transmitted to the controller, which calculates the coordinates of the touch point.

In earlier models of capacitive screens, D.C.- this simplified the design, but if the user had poor contact with the ground, it led to failures.

Capacitive touch screens are reliable, about 200 million clicks (about 6 and a half years of clicks with an interval of one second), do not leak liquids and tolerate non-conductive contaminants very well. Transparency at 90%. However, the conductive coating located directly on the outer surface is still vulnerable. Therefore, capacitive screens are widely used in machines only installed in a weather-protected room. They do not respond to a gloved hand.

It is worth noting that due to differences in terminology, surface- and projected-capacitive screens are often confused. According to the classification used in this article, the screen of, for example, the iPhone is projected capacitive, not capacitive.

Projected capacitive touch screens

A grid of electrodes is applied on the inside of the screen. The electrode together with the human body forms a capacitor; the electronics measures the capacitance of this capacitor (supplies a current pulse and measures the voltage).

Samsung has managed to install sensitive electrodes directly between the subpixels of the AMOLED screen, which simplifies the design and increases transparency.

The transparency of such screens is up to 90%, the temperature range is extremely wide. Very durable (the bottleneck is the complex electronics that process clicks). PESE can use glass up to 18 mm thick, which results in extreme vandal resistance. They do not react to non-conductive contaminants; conductive ones are easily suppressed using software methods. Therefore, projected capacitive touch screens are widely used in personal electronics and in vending machines, including those installed on the street. Many varieties support multi-touch.

Touch screens based on surface acoustic waves

The screen is a glass panel with piezoelectric transducers (PETs) located in the corners. At the edges of the panel there are reflective and receiving sensors. The operating principle of such a screen is as follows. A special controller generates a high-frequency electrical signal and sends it to the probe. The probe converts this signal into a surfactant, and the reflective sensors reflect it accordingly.

These reflected waves are received by the corresponding sensors and sent to the probe. The probes, in turn, receive the reflected waves and convert them into an electrical signal, which is then analyzed by the controller. When you touch the screen with your finger, some of the energy from the acoustic waves is absorbed. The receivers record this change, and the microcontroller calculates the position of the touch point. Reacts to touch with an object capable of absorbing the wave (finger, gloved hand, porous rubber).

The main advantage of a surface acoustic wave (SAW) screen is the ability to track not only the coordinates of a point, but also the pressing force (here, rather, the ability to accurately determine the radius or area of pressing), due to the fact that the degree of absorption of acoustic waves depends on the pressure at the point touch (the screen does not bend under finger pressure and is not deformed, so the pressing force does not entail qualitative changes in the controller’s processing of data on the coordinates of the impact, which only records the area that overlaps the path of the acoustic pulses).

This device has very high transparency because the light from the imaging device passes through glass that does not contain resistive or conductive coatings. In some cases, glass is not used at all to combat glare, and emitters, receivers and reflectors are attached directly to the screen of the display device. Despite the complexity of the design, these screens are quite durable. According to, for example, the American company Tyco Electronics and the Taiwanese company GeneralTouch, they can withstand up to 50 million touches at one point, which exceeds the life of a 5-wire resistive screen.

Surfactant-based screens are used mainly in slot machines, in protected help systems and educational institutions. As a rule, surfactant screens are divided into regular ones - 3 mm thick, and vandal-resistant ones - 6 mm. The latter can withstand a blow from the fist of an average man or a drop of a metal ball weighing 0.5 kg from a height of 1.3 meters (according to Elo Touch Systems). The market offers options for connecting to a computer both via the RS232 interface and via the USB interface. At the moment, controllers for surfactant touch screens that support both types of connection - combo (data from Elo Touch Systems) are more popular.

The main disadvantage of a surfactant screen is malfunctions in the presence of vibration or when exposed to acoustic noise, as well as when the screen is dirty. Any foreign object placed on the screen (for example, chewing gum) completely blocks its operation. Besides, this technology requires contact with an object that necessarily absorbs acoustic waves - that is, for example, a plastic bank card is not applicable in this case.

The accuracy of these screens is higher than matrix ones, but lower than traditional capacitive ones. As a rule, they are not used for drawing and entering text.

Infrared touch screens

Working principle of infrared touchpad simple - the grid formed by horizontal and vertical infrared rays is interrupted when any object touches the monitor. The controller determines the location where the beam was interrupted.

Infrared touch screens are sensitive to contamination and are therefore used where image quality is important, for example, in e-books. Due to its simplicity and maintainability, the scheme is popular with the military. Intercom keypads are often made using this principle. This type screen is used in numerous Neonode phones.

Optical touch screens

The glass panel is equipped with infrared illumination. At the glass-air interface, total internal reflection is obtained; at the glass-foreign object interface, light is scattered. All that remains is to capture the scattering picture; for this there are two technologies:

In projection screens, a camera is placed next to the projector.

This is how Microsoft PixelSense works, for example.

Or the additional fourth subpixel of the LCD screen is made photosensitive.

They allow you to distinguish hand presses from presses with any objects, there is multi-touch. Large touch surfaces are possible, up to a blackboard.

Strain gauge touch screens

React to screen deformation. The accuracy of strain gauge screens is low, but they are highly resistant to vandalism. The main application is ATMs, ticket machines and other devices located on the street.

DST touch screens

The DST (Dispersive Signal Technology) touch screen detects the piezoelectric effect in the glass. It is possible to press the screen with your hand or any object.

A distinctive feature is the high reaction speed and the ability to work in conditions of heavily soiled screens. However, the finger must move; the system does not notice a stationary finger.

We all use mobile phones, most of us use modern mobile gadgets: smartphones and tablets, which can be controlled by pressing the screen, or, more precisely, by touching the screen.

It's quite convenient. But what kind of technology allows you to give commands to your smartphone with simple taps? Let's figure it out.

Touchscreen is a touch screen that allows you to give commands to the device by interacting with elements using touches. The word “touchscreen” is derived from two English words “touch” (touch, touch) and “screen” (screen).

According to the principle of operation, touchscreens are divided into resistive and capacitive.

Touchscreen (touch screen)

Resistive touch screens

A resistive touchscreen is a touch screen that is a flexible transparent membrane with a conductive coating. This coating is also called “resistive”, hence the name. Under the membrane there is glass with a layer that conducts current.

Resistive touch screens work as follows. When you press the screen, the glass closes with the membrane at a certain point, which allows the microprocessor to calculate the coordinates of the touch. The more precise the touch (hitting the desired element on the screen with a minimal surface), the better. Therefore, it is better to work with resistive touchscreens using a stylus.

Resistive touch screens were used in old PDAs, smartphones, and are used in ATMs and payment terminals.

Resistive touch screen

Explicit pros Such touchscreens are cheap to produce (compared to capacitive ones) and the ability to press any objects on the screen (this, however, is not always a plus).

TO cons These include low strength, low durability, the inability to implement multi-touch (the perception of simultaneously pressing several parts of the screen), a large number of errors when processing sliding gestures (for example, flipping or scrolling).

Capacitive touch screens

So we come to the familiar capacitive touch screens. These are installed in all modern smartphones and tablets. But they are also divided into two subtypes: conventional capacitive and projection-capacitive touchscreens.

Conventional capacitive touch screens

In this case, the glass is covered with a conductive layer, and in the corners of the screen there are electrodes that supply alternating voltage. When you touch the screen, current leaks. Depending on the distance to each of the corners where the electrodes are located, the pressing point is calculated. Naturally, such a press only works with a conductive object, for example, a human finger. When using this technology, cartooning cannot be implemented either.

More modern screens have a grid of electrodes on the inside of the display. Touching one of them with your finger leads to the formation of a capacitor, the capacitance of which is measured for subsequent calculations and actions. Such screens allow you to implement multi-touch, since you can create several capacitors at the same time. With other types of touch screens, calculating multiple taps at once is not possible.

Left - capacitive touch screen, right - projected capacitive touch screen

TO pros The advantages of capacitive screens include the ability to implement multi-touch (only in projected capacitive screens), reliability, no need for pressure (pressing hard) on the display, and high light transmission.

TO cons The disadvantages of capacitive touchscreens include the price (they are quite expensive to produce) and the inability to work with a stylus. The latter is not a disadvantage for everyone. In addition, there are now special styluses for working with capacitive touchscreens. So the main disadvantage remains the higher production cost compared to resistive touchscreens.

There are also other touchscreens and touchscreens, but everyday life they are much less common.

Touch screens:

- Resistive touch screens

- Matrix touch screens

- Surface capacitive touch screens

- Projected capacitive touch screens

- Touch screens based on surface acoustic waves

- Infrared touch screens

- Optical touch screens

- Strain gauge touch screens

- Induction touch screens