Testing the cable with a 0.4 sq. megohmmeter. Cable insulation resistance

The quality of the cable insulation layer greatly affects the reliability of the electrical installation as a whole. It can change both during production at the factory and during storage, transportation, installation of the circuit, and, especially, during its operation.

For example, moisture that gets inside the insulation at subzero temperatures will freeze and change its electrically conductive properties. Determining its presence in this situation is very problematic.

Types of checks

Constant attention is paid to the quality of insulation, which is comprehensively implemented:

periodic mandatory inspections by trained personnel;

automatic tracking by special monitoring devices during the execution of a constant technological cycle.

During cable assessment, personnel determine its mechanical condition and check its electrical characteristics.

During an external inspection, which is mandatory during any inspection, quite often you can see only the ends of the cable brought out for connection, and the rest of it is hidden from view. But even with full access It is impossible to determine the quality of the insulating layer.

Electrical tests make it possible to identify all insulation defects, which allows us to draw a conclusion about the suitability of the cable for further use and provide guarantees for its use. They are divided according to the degree of complexity into:

1. measurements;

2. tests.

The first method is used to assess quality in the following cases:

after purchase, before installation in the electrical circuit begins, so as not to waste time on laying and subsequent dismantling of a faulty cable;

after completing installation work to assess their quality;

when the tests are completed. This allows you to assess the serviceability of insulation exposed to increased voltage;

periodically during operation to monitor safety technical characteristics under the influence of operating current loads or environmental factors.

Cable insulation tests are carried out after its installation before connection to operation or periodically during operation as necessary.

How the cable works

To explain the principle of electrical testing, let's consider the structure of a simple, commonly found cable of the VVGng brand.

Each of its current-carrying conductors is equipped with its own layer of dielectric coating, which insulates it from neighboring conductors and leakage to ground. Current-carrying wires are placed in the core and protected by a sheath.

In other words, any electrical cable consists of metal wires, most often based on copper or aluminum, and an insulation layer that protects the conductors from leakage currents and short circuits between all phases and the ground.

Each cable is designed to transmit a specific type of energy under different operating conditions. It is subject to certain, specific requirements. They must be familiarized with before carrying out electrical measurements.

Instruments for testing

Sometimes novice electricians, to measure the insulation of a cable or electrical wiring, use testers or multimeters, which have a scale for measuring resistance in kiloOhms and megaOhms. This is a grave mistake. Such devices are designed to evaluate the parameters of radio components and operate from low-power batteries. They are not able to create the necessary load on the insulation of cable lines.

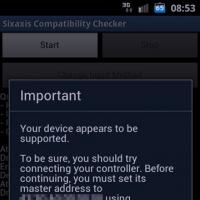

Special devices serve these purposes - megohmmeters, called “megohmmeters” in electricians’ jargon. They have many designs and modifications.

Before you start using any device, you must check its serviceability each time:

external inspection;

assessment of the timing of inspections by the metrological laboratory based on the state of its mark on the body. Safety rules do not allow the use of a measuring device with a broken mark, even when there is a passport about the inspection carried out before its expiration;

checking the timing of periodic insulation tests of the high-voltage part of the device by an electrical laboratory. A faulty megohmmeter or damaged connecting wires can cause electric shock to personnel.

control measurement of known resistance.

Attention! All work with a megohmmeter is classified as dangerous! They can only be performed by trained, tested and approved by the commission personnel with electrical safety group III and higher.

Technical issues of preparing cables for insulation measurements and testing

Please note that the organizational part is discussed here very briefly and not completely. This is a big, important topic for another article.

1. All measurement work must be carried out on the cable with the voltage removed from it and, as a rule, the surrounding equipment. The effect of induced electric fields on the measurement circuit must be excluded.

This is dictated not only by safety, but also by the operating principle of the device, which is based on supplying a calibrated voltage to the circuit from its own generator and measuring the currents generated in it. The scale divisions of analog instruments and the readings of digital models in Ohms are proportional to the magnitude of the resulting leakage currents.

2. The cable connected to the equipment must be disconnected from all sides.

Otherwise, the insulation resistance of not only its cores, but the entire remaining connected circuit will be measured. Sometimes this technique is used to speed up work. But, in any case, to obtain reliable information, the equipment connection diagram must be taken into account.

To disconnect a cable, its ends are separated or the switching devices to which it is connected are disconnected.

In the latter case, if negative results are obtained, it is necessary to check the insulation of the circuits of these devices.

3. The cable length can reach a large value on the order of a kilometer. At the remote end, at the most unexpected moment, people may appear and, through their actions, influence the measurement result or suffer from high voltage applied to the cable from the megohmmeter. This must be prevented by running .

Peculiarities safe use megohmmeter and measurement technology

Long cables laid in electrical networks near a working one may be under induced voltage, and when disconnected from the ground loop, have a residual charge, the energy of which can harm the human body. The megohmmeter generates increased voltage, which is applied to the cable cores insulated from the ground. In this case, a capacitive charge is also created: each core acts as the plate of a capacitor.

Both of these factors together impose a safety condition - to use portable grounding when measuring the resistance of each core, both individually and in combination. Without it, touching the metal parts of the cable without using protective electrical equipment is strictly prohibited.

How to measure the insulation resistance of conductors relative to ground

Consider, as an example, checking the insulation resistance of one core relative to ground.

The first end of the portable grounding is initially securely attached to the ground loop and is no longer removed until the electrical checks are completed. One of the two wires of the megohmmeter is also connected here.

The second end of the grounding, equipped with an insulated tip with a safety ring and a clip for quick connection of the “Crocodile” type, in compliance with safety rules, is connected to the metal core of the cable to remove the capacitive charge from it. Then, without removing the grounding, the output of the second wire from the megohmmeter is switched here.

Only after this is the grounding “crocodile” allowed to be removed for measurements by applying voltage to the prepared electrical circuit. The measurement time must be at least one minute. This is necessary to stabilize transient processes in the circuit and obtain accurate results.

When the megohmmeter generator is stopped, it is impossible to disconnect the device from the circuit due to the capacitive charge present on it. To remove it, it is necessary to reuse the second end of the portable grounding and apply it to the core being tested.

The conductor coming from the megohmmeter is removed from the core after connecting a portable ground to it. Thus, the circuits of the measuring device are always connected to the test circuit only when grounding is installed, which is removed at the time of measurement.

The described check of the cable insulation condition with a megohmmeter for phase C is demonstrated by a sequence of drawings.

In the given example, to simplify the understanding of the technology, the actions with other conductors remaining under induced voltage, which must be removed by installing a short circuit with additional portable grounding, are not described, which significantly complicates the circuit and measurements.

In practice, in order to speed up the work of checking the phase insulation relative to the ground, all cable cores are connected to a short circuit. This operation must be performed by personnel authorized to work under voltage. She's dangerous.

In the example under consideration, these are phases PE, N, A, B, C. Next, measurements are carried out using the above technology for all parallel-connected chains at once.

Usually the cables are in good condition, then such a check is sufficient. If you get an unsatisfactory result, you will have to carry out all measurements in phases.

How to measure insulation resistance between cable cores

In order to improve understanding of the process, we will simplify that the cable is not under the influence of induced voltage and has a short length, which does not create significant capacitive charges. This will allow us not to describe actions with portable grounding that must be performed using the technology already discussed.

Before taking measurements, it is necessary to inspect the assembled circuit and check it using a voltage absence indicator on the cores. They must be moved apart without touching each other or any surrounding objects. The megohmmeter is connected at one end to the phase relative to which the measurement will be performed, and the second wire alternately switches the remaining phases for measurements.

In our example, the insulation of all cores is measured one by one relative to the PE phase. When it ends, we select the next phase, for example, N as the common one. In the same way, we take measurements relative to it, but we no longer work with the previous phase. Its insulation between all cores has been checked.

Then we select the next phase as a common one and continue measurements with the remaining cores. In this way we sort through everything possible combinations connections between the cores to analyze the state of their insulation.

Once again, I would like to draw your attention to the fact that this test is described for a cable that is not subject to induced voltage and does not have a large capacitive charge. It is impossible to blindly copy it for all possible cases.

How to document measurement results

The date and scope of the inspection, information about the composition of the team, the measuring instruments used, the connection diagram, temperature conditions, work conditions, all obtained electrical characteristics must be kept in a record. They may be required in the future for a working cable and serve as evidence of a fault for a rejected product.

Therefore, a protocol is drawn up for the measurements taken, certified by the signature of the work manufacturer. To draw it up, you can use an ordinary notepad, but it is more convenient to use a pre-prepared form containing information about the sequence of operations, reminders on safety measures, basic technical standards and tables prepared for filling out.

It is convenient to create such a document once using a computer, and then simply print it on a printer. This method saves time on preparation, registration of measurement results, and gives the document an official appearance.

Features of insulation testing

This work is carried out using special stands containing extraneous high-voltage sources with measuring instruments, which are classified as dangerous. It is performed by specially trained and authorized personnel, who are organizationally part of a separate laboratory or service at enterprises.

The testing technology is much like the insulation measurement process, but uses more powerful energy sources and high-precision measuring instruments.

The test results, as with measurements, are documented in a protocol.

Operation of insulation monitoring devices

A lot of attention is paid to automatic checking of the insulation condition of electrical equipment in the energy sector. It can significantly increase the reliability of power supply to consumers. However, this is a separate large topic that requires additional disclosure in another article.

Getting started cable insulation resistance measurement It is important to take into account the temperature of the environment. Why is this so?

This is due to the fact that at sub-zero temperatures, water molecules in the cable mass will be in a frozen state, actually in the form of ice. And as you know, ice is a dielectric and does not conduct current.

So, when determining the insulation resistance at sub-zero temperatures, it is these particles of frozen water that will not be detected.

To calculate the conductor resistance, you can use the conductor resistance calculator.

Instruments and means for measuring cable insulation resistance.

The next point when measuring the insulation resistance of cable lines will be the measuring instruments themselves.

The most popular device for measuring insulation resistance among our electrical laboratory workers is the MIC-2500 device.

Using this device manufactured by Sonel, you can not only take measurements of the resistance of cable lines, cords, wires, electrical equipment (transformers, switches, motors, etc.), but also determine the level of wear and moisture level of the insulation.

It is worth noting that it is the MIC-2500 device that is included in the state register of approved insulation resistance measurements.

According to the instructions, the MIC-2500 device must undergo annual state verification. After the verification procedure, a hologram and a stamp are applied to the device, which confirm the verification. The stamp indicates information about the date of scheduled verification and serial number measuring device.

Only serviceable and verified instruments are allowed to work with insulation resistance measurements.

Insulation resistance standards for various cables.

To determine the standard cable insulation resistance, you need to classify them. Cables according to their functional purpose are divided into:

- above 1000 (V) - high-voltage power

- below 1000 (V) - low-voltage power

- control cables - (protection and automation circuits, secondary switchgear circuits, control circuits, power supply circuits for electric drives of switches, separators, short circuiters, etc.)

Insulation resistance measurement for both high-voltage cables and low-voltage cables is carried out with a megohmmeter for a voltage of 2500 (V). And control cables are measured at a voltage of 500-2500 (V).

Each cable has its own insulation resistance standards. According to PTEEP and PUE.

High-voltage power cables above 1000 (V) - the insulation resistance must reach at least 10 (MΩ)

Low voltage power cables below 1000 (V) - insulation resistance should not fall below 0.5 (MΩ)

Control cables - insulation resistance should not fall below 1 (MΩ)

Algorithm for measuring the insulation resistance of high-voltage power cables.

To understand and simplify the process of performing measurement work insulation resistance in high voltage power cables, we recommend the procedure for taking measurements.

1. Check the absence of voltage on the cable using a high voltage indicator

2. We install a test ground using special clamps on the cable conductors on the side where we will carry out the measurement.

3. On the other side of the cable we leave free conductors, while we separate them at a sufficient distance from each other.

4. We place warning information posters. It is advisable to place a person on the other side to monitor safety while measuring with a megohmmeter.

5. We measure each core for 1 minute with a 2500 (V) megohmmeter to obtain the indicators insulation resistance of the power cable.

For example, we measure the insulation resistance on the conductor of phase “C”. At the same time, we place the grounding on the conductors of phases “B” and “A”. We connect one end of the megohmmeter to grounding, or, more simply, to “ground”. The second end is to the core of phase “C”.

Visually it looks like this:

6. We write down the measurement data in the process of work in a notepad.

Methodology for measuring insulation resistance of low-voltage power cables.

As for measuring the insulation of low-voltage power cables, the measurement technique differs slightly from that described above.

Likewise:

1. We check that there is no voltage on the cable using protective equipment designed for work in electrical installations.

2. On the other side of the cable, we separate the conductors at a sufficient distance from each other and leave them free.

3. We place prohibition and warning posters. We leave a person on the other side to monitor safety.

4.Measurement insulation resistance of low voltage power cable run a megohmmeter at 2500 (V) for 1 minute:

- between phase conductors (A-B, B-C, A-C)

- between phase conductors and zero (A-N, B-N, C-N)

- between phase conductors and ground (A-PE, B-PE, C-PE), if the cable is five-core

- between zero and ground (N-PE), having previously disconnected zero from the zero bus

6. We record the obtained insulation resistance measurements in a notebook.

Methodology for measuring the insulation resistance of control cables.

A special feature of measuring the insulation resistance of control cables is that the cable cores can not be disconnected from the circuit and measurements can be taken together with the electrical equipment.

The insulation resistance of the control cable is measured using a familiar algorithm.

1. We check that there is no voltage on the cable using protective equipment that is designed for work in electrical installations.

2. We measure the insulation resistance of the control cable with a megohmmeter of 500-2500 (V) in the following sequence.

First, we connect one terminal of the megohmmeter to the core being tested. We connect the remaining cores of the control cable to each other and to the ground. To the second terminal of the megohmmeter we connect either the ground or any other non-tested conductor.

We take 1 minute to measure the core being tested. Then we return this core to the rest of the cable cores and measure each core one by one.

3. We record all the obtained indicators for measuring the insulation resistance of the control cable in a notebook.

Protocol for measuring cable insulation resistance.

All of the above electrical measurements, after obtaining data on the insulation resistance of the cable, it is necessary to subject it to a comparative analysis with the requirements and standards of the PUE and PTEEP. Based on the comparison, it is necessary to formulate a conclusion about the suitability of the cable for subsequent operation and draw up a protocol for measuring insulation resistance.

Any cable testing, laid out like in the ground, so underground, are organized in strict accordance with the requirements of PUE 7 and PTEEP. These issues are set out in Chapter 1.8 of the first document (clause 1.8.40) and in the third appendix of the second document (clause 6).

During the tests carried out by our electrical laboratory in Moscow, existing weak points in the insulation of the cable being tested are determined, and defects in the installation of couplings: connecting and end couplings are identified.

It's important to remember that power cable testing must be carried out in normal weather conditions. And also the fact that our team is always ready urgently travel to order to any area of the city and region.

Cable insulation tests, manufactured outside of Russia, and laid in a power line, is carried out according to the manufacturer’s instructions.

Measurement values carried out electrical laboratory, are necessarily compared with the results of previous ones, including those performed in the factory.

The results obtained during the testing process are entered into cable test report, drawn up according to the existing form. Testing CL under voltage 0.4 kV(up to 1 kV) are carried out in accordance with paragraphs 4, 2, 1. At a voltage value of more than 1 kV ( 6 kV, 10 kV) clause 3 is added.

During the testing process departure to the CL installation site, where the following parameters are checked:

l Phasing and integrity of CL cores;

l The insulation resistance value of the cable being tested is measured (up to 1 kV, the resulting value must be ≥ 0.5 MOhm. If carried out 10 kV cable testing, it should be noted that there are no existing standards. And the recommended value is ≥ 10 MΩ).

Insulation resistance is measured only when there is no voltage on the cable line, which is preliminarily checked using special protective equipment.

High voltage cable testing;

In single-core cable lines, current distribution is measured;

CLs are tested with increased voltage.

Price The tests performed depend on what technique was used.

The resistance of a cable's insulating layer is one of the most important parameters of its performance. If you bought a cable and it was stored in a warehouse for some time, do not think that its insulation will be the same as when you bought it. Insulation can deteriorate both under unsatisfactory storage conditions and during operation and installation. In order to reveal everything possible problems and the cable insulation is checked with a megohmmeter.

Causes of poor cable insulation

There are several factors affecting the insulating properties of cables:

In order to identify an insulation problem in time, you will need a special device - a megohmmeter. These devices are of the old type (mechanical, where you need to rotate the handle):

and a new model - electronic:

and a new model - electronic:

Let's consider the operation of these devices.

Let's consider the operation of these devices.

Safety rules

Checking the cable insulation with a megohmmeter is carried out only with the equipment disconnected and de-energized.

The megaohmmeter is capable of producing high voltage (certain types up to 5000 Volts), so when working with it, strictly follow the following rules:

Preparatory work

The cable under test must be prepared before testing.

To do this:

To do this:

- ⚡ check that there is no voltage on the cable cores

- ⚡

long cables may have induced or residual voltage

Therefore, before each measurement, using a separate piece of wire or portable grounding, wearing dielectric gloves, it is necessary to touch the core and the grounded body or grounding loop to remove this charge; - ⚡

disconnect the cable from the connected equipment.

This must be done so that when checking the cable insulation with a megohmmeter, only the cable itself is involved in the test, without the equipment or machines to which it is connected. Disconnection must be done on both sides of the cable. Sometimes this is not done to speed up work. First, a measurement is taken, and if it shows a negative result, then only after that the wires are pulled back.

Checking the megohmmeter

Before checking the cable insulation with a megohmmeter, it is necessary to test the operation of the device itself.

Here's how to do it on the M4100 megohmmeter. The device has 2 scales: the upper one for measurements in megaohms and the lower one for measurements in kiloohms.

To work in megaohms:

- ⚡ connect the ends of the probe wires to the two left terminals. The probes must be open;

- ⚡ rotate the knob and watch the arrow readings. If the device is working properly, it will tend to the left - towards infinity;

- ⚡ close the probes together. When you rotate the knob, the arrow should deflect to the right to zero.

To work in kilo-ohms:

- ⚡ Place a jumper between the 2 left terminals and connect one of the ends there. The second end is connected to the rightmost terminal. The probes are open;

- ⚡ Rotate the knob and watch the readings. When the device is working properly, the arrow deviates as far as possible to the right;

- ⚡ After closing the probes and rotating the knob, the arrow will tend to zero on the lower scale (i.e. to the left).

Working with megaohmmeter M4100

- First of all, check that there is no voltage on the cable

- ground all conductors

- place the device on a flat surface

- When measuring conductor insulation to ground, one of the probes is connected to the wire, the other to the armor or grounding device. Then remove the grounding only from the core being measured;

- Rotate the knob evenly for 60 seconds. Rotation speed is two revolutions per second. At 60 seconds, note the readings of the device;

- after each measurement, remove the residual charge from the core and wires of the megohmmeter by touching them to ground.

It is enough to test household networks and home wiring with a voltage of 500 Volts. The minimum value that a cable insulation test with a megohmmeter should show in this case is 0.5 mOhm.

In industrial power networks, cables are tested with 2500 Volt megaohmmeters. The insulation resistance must be at least 10 mOhm.

Working with an electronic megohmmeter

How often is cable insulation checked with a megameter?

- The first measurement is taken at the manufacturer's factory

- Before installation on site

- After installation before applying voltage

- During operation, when defects are detected or during maintenance, once every three years.

- ⚡ some people get confused with the scales of the M4100 device. Where is the measurement scale in megaohms located, and where in kiloohms? In order not to forget, use the hint: megaohm (mOhm) as a unit of measurement is higher than kiloohm (kOhm), respectively, and its scale is higher!

- ⚡ Before measuring, clean the ends of the cable cores from dirt. Dirty insulation may give poor results, although the cable itself will be fine;

- ⚡ The measuring leads of the megohmmeter itself must have an insulation of at least 10 mOhm. Do not use strange scraps or pieces of old wires. You will only worsen the measurement readings and will not know the exact results;

- ⚡ when checking a cable in the circuit of which there is a meter, be sure to disconnect all phase conductors and the neutral conductor from the housing or busbar. Otherwise, due to the metering device, you will have megohmmeter readings, as if the cable cores are giving short circuit among themselves;

- ⚡ If you sequentially measure individual sections of wiring, always disconnect the neutral conductors from the common bus. Otherwise, you will get the same measurements on all cables. And these results will be equal to the worst resistance of one of the connected cables;

- ⚡ if the cable is long (more than 1 km), with a large capacity, then the residual charge must be removed using a special rod. Otherwise you can create a big “boom” right before your eyes;

- ⚡ When taking measurements in lighting networks, unscrew the incandescent light bulbs from the lamps and leave the switches themselves turned on. For gas discharge lamps measurements can be carried out without removing the light bulbs from the housings, but with the obligatory unscrewing of the starter.